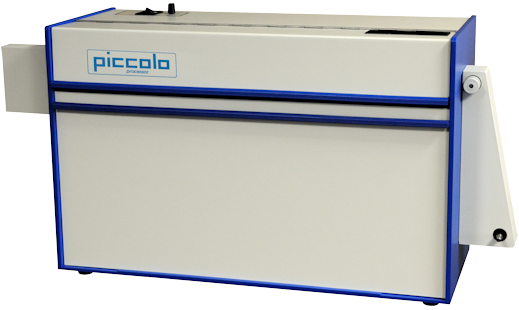

piccolo

Processor for 16 mm roll films

The processor operates according a patented principle and is specially outlined for the application of 16 mm microfilms.

Each user will be thrilled by the simple handling of this unit.

After inserting the exposed 16 mm film into the film-cassette, the end of the film is tracked directly into the rack (without leader). Afterwards the film horizontally passes through the developing process in the following order of succession: developer, fixer, 1st rinse, 2nd rinse, drying.

After 30 sec. the film can be threaded into the take up-spool.

The special Piccolo chemical set (4 bottles of 1 l each: developer, fixer, 1st rinse, 2nd rinse) is directly connected to the unit. The chemicals are taken out of the bottles and transported to the film by pumps, through an electronically controlled heat exchanger. From here the chemicals are running back into the bottles.

After about 8 films of 16 mm/ 30m, or a life time of one week the chemical set is used up.

The unique features are:

• Simple inserting of the film into the rack

• Simple handling of the chemicals

• No water supply and water discharge hose necessary

• Extremely low power consumption: heating-up phase 800 W/stand by 200 W

Technical Data:

• Film: 16 mm roll film

• Time of passage: 1m / minute

• Chemical temperature: regulated, adjustable 28-38°C

• Chemicals: 4 bottles of 1l each: developer, fixer, 1st rinse and 2nd rinse

• With regard to the archival capability (residual thiosulfate) it is necessary to use the Staude chemical set, which is specially produced for this processor

• Power supply: 230V / 50Hz / 800W (Option: 110V transformer)

• Dimensions and Weight: H/W/D: 42 x 67 x 28 cm, 22KG

How does it work? Look at the video